Newly installed tech promises to reduce energy costs, produce better ice, and narrow carbon footprint at community centre

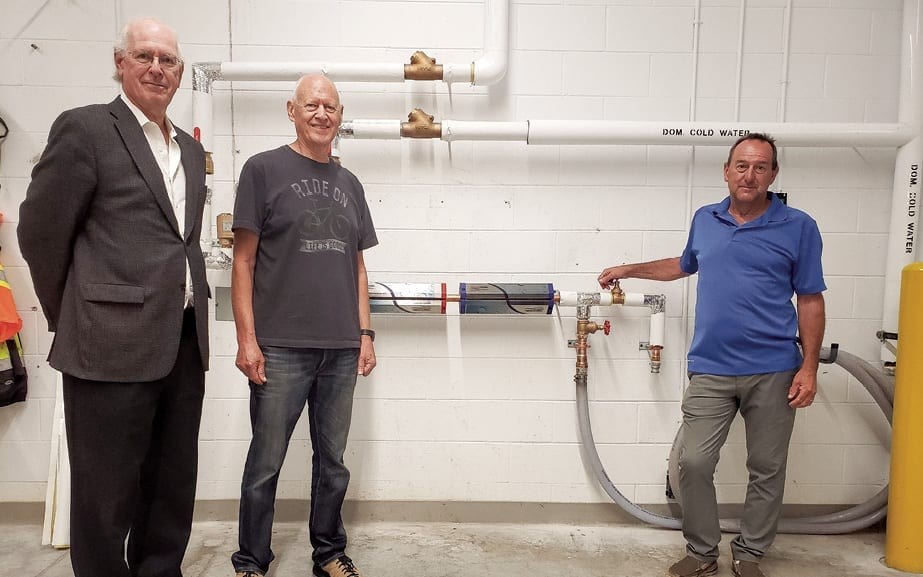

Meridian Centre staff gathered round last Friday to watch two fire-extinguisher-sized cannisters being attached to the copper tubing that feeds water from the mains to the twin arenas’ ice surfaces. The two cannisters are the component parts of the Magnavitalis system, a German developed and manufactured technology that significantly reduces the temperature of the water needed in the ice making process.

The “Magnetic Vortex” unit and “Bio-communicator” unit were screwed into place by Magnavitalis Canadian representative, Peter Schurmann, and veteran ice maker Clayton Perry, who was an early adopter of the technology in Mississauga. According to Schurmann, the system uses no chemicals or electricity to “de-cluster” the water molecules passing through the pipe “by means of rare earth magnetic forces and recombines them into a denser form with a natural—spring water like— orientation.” All of which means that the treated water to make ice can be 70 degrees Fahrenheit instead of the 130 to 140 degrees necessary in traditional ice-making.

If the science is a bit vague, the results are impressive. Available since 2009, the Magnavitalis system is currently in use in some 70 stadiums in Switzerland, Austria, and Germany, where rinks are reporting savings as high as $50,000 per rink per year, albeit with natural gas prices that are about five times higher than those in North America. Still, installations in Mississauga and Oakville are reporting savings of some $40,000 per year for a twin-rink facility. The savings are a direct result of the reduction in temperature of the ice-making water. Compressor runtimes are drastically reduced, saving electricity and maintenance, while natural gas costs are cut, and water usage is reduced by as much as 20 percent.

The $20,000 purchase of the Magnavitalis system was initiated by the Town’s Utility Sustainability Committee, whose members include Town staff and members of the public, one of whom, Dave Cano, had experienced the technology in Oakville. The committee investigated the concept of cold water ice flooding and considered several rival systems before recommending Magnavitalis to Town Council. Council approved the purchase, and, according to the Director of Recreation, Culture and Wellness, Vickie vanRavenswaay, efforts are underway to offset the cost through grants from the utility company Enbridge.

Spearheading the drive to obtain the technology was Councillor Bob Hildebrandt, who says he ran in the last election “to work toward a more efficient operation of the MCC.” A retired Foster-Wheeler engineer, he was engaged in the earliest days of the planning of the MCC, but felt his ideas were not getting traction with the former council or the community centre planners, hence his decision to run for council.

The Magnavitalis system impressed him, Hildebrandt says, when his son was involved with the Canadian Junior Hockey Team December Selection Camp at the Oakville rinks, where it was in use.

“When they said it was great ice, I listened,” he says. “Hockey players know their ice.”

Clayton Perry had been the ice-maker for 30 years at Mississauga’s Port Credit Arena rink, where the Magnavitalis system was first proposed.

“I was skeptical,” he says, “but they offered to install it free for six months, so we really had nothing to lose.”

Within the six months, they discovered not only significant savings in natural gas and electricity (700 fewer hours per year of running the compressor), but clearer, harder ice. Now Oakville is contemplating the purchase of the units for four more of its arenas.

Peter Schurmann and the Magnavitalis team have left a detailed spreadsheet with community centre staff so they can record the temperature of the water used for making ice, the temperature of the ice surface, the run-time of the facility’s compressors, and other measurements that will verify whether the promised savings have been realized. Even the most pessimistic of the projections tossed around by Hildebrandt and Schurmann suggest that savings of $40,000 per year are possible. The resulting reduction in fuel consumption was claimed to reduce the MCC’s carbon footprint by 380 tonnes, or, as Hildebrandt asserts, “the equivalent of 20 residential homes heated by natural gas each year.”

Brian Secord, the ice-maker at the MCC, hopes to be putting down the first layers of ice this week using the new system. A year from now he and the Utility Sustainability Committee and Councillor Hildebrandt hope to be able to point to their cost spreadsheet and their ice surface with proof that the promises of the Magnavitalis system have been fulfilled.